Grout Pumps (Low Pressure)

The Colmono range of grout pumps have been market leaders for many years and are available either as dedicated pumps as detailed below, or in combination with a colloidal mixer (see Colloidal Grout Mixer / Pump Units).

The Colmono range of grout pumps have been market leaders for many years and are available either as dedicated pumps as detailed below, or in combination with a colloidal mixer (see Colloidal Grout Mixer / Pump Units).

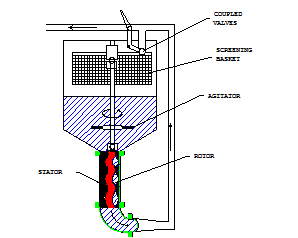

The pump is shown schematically in the diagram (above). Mixed grout is stored in the cylindrical tank and is kept agitated by paddles on the drive shaft. The same drive shaft also turns the rotor of the progressive cavity pump fitted below the tank. The control lever operates two valves permitting either recirculation or pumping to be achieved.

This layout with the progressive pump vertical offers dramatic advantages. Firstly there are no bearings and seals in contact with the grout; the gearbox is mounted on top of the tank, well above the level of the grout. Secondly the vertical layout simplifies cleaning. The whole of the drive shaft is exposed when the tank is empty and can be simply washed down with a hose. Also any sand particles or debris tend to fall down through to the bottom of the pump rather than lodging in the depressions of the stator where they can cause damage.

Where applications or products permit, other layouts can be provided to give outputs up to 100 cubic metres per hour and pressures up to 40 bar.

Hand operated and air operated diaphragm pumps are also available.

| Model | Description | Max Output (M3/Hour) | Batch Capacity (Litres) | Max Press (Bars) | Drive Options Electric (KW) | Drive Diesel (HP) | Drive Options Air (M3/Min) |

|---|---|---|---|---|---|---|---|

| Colmono 2000 | Grout Pump (Progr.cavity) | 20 | 2000 | 10 | 15 | 15 | |

| Colmono 10 FBO | Grout Pump (Progr.cavity) | 16 | 1300 | 10 | 11 | 11 | |

| Colmono 10 FBO | Grout Pump (Progr.cavity) | 8 | 370 | 10 | 5.5 | 7.5 | |

| Colmono 4 | Grout Pump (Progr.cavity) | 2.5 | 70 | 10 | 4 | 4 | |

| Sandpiper SB1.5 | Grout Pump (Diaphragm) | 5 | 6 | 1.5 | |||

| Handpump | Grout Pump (Diaphragm) | 1.3 | 14 |